Smart Shape Technology

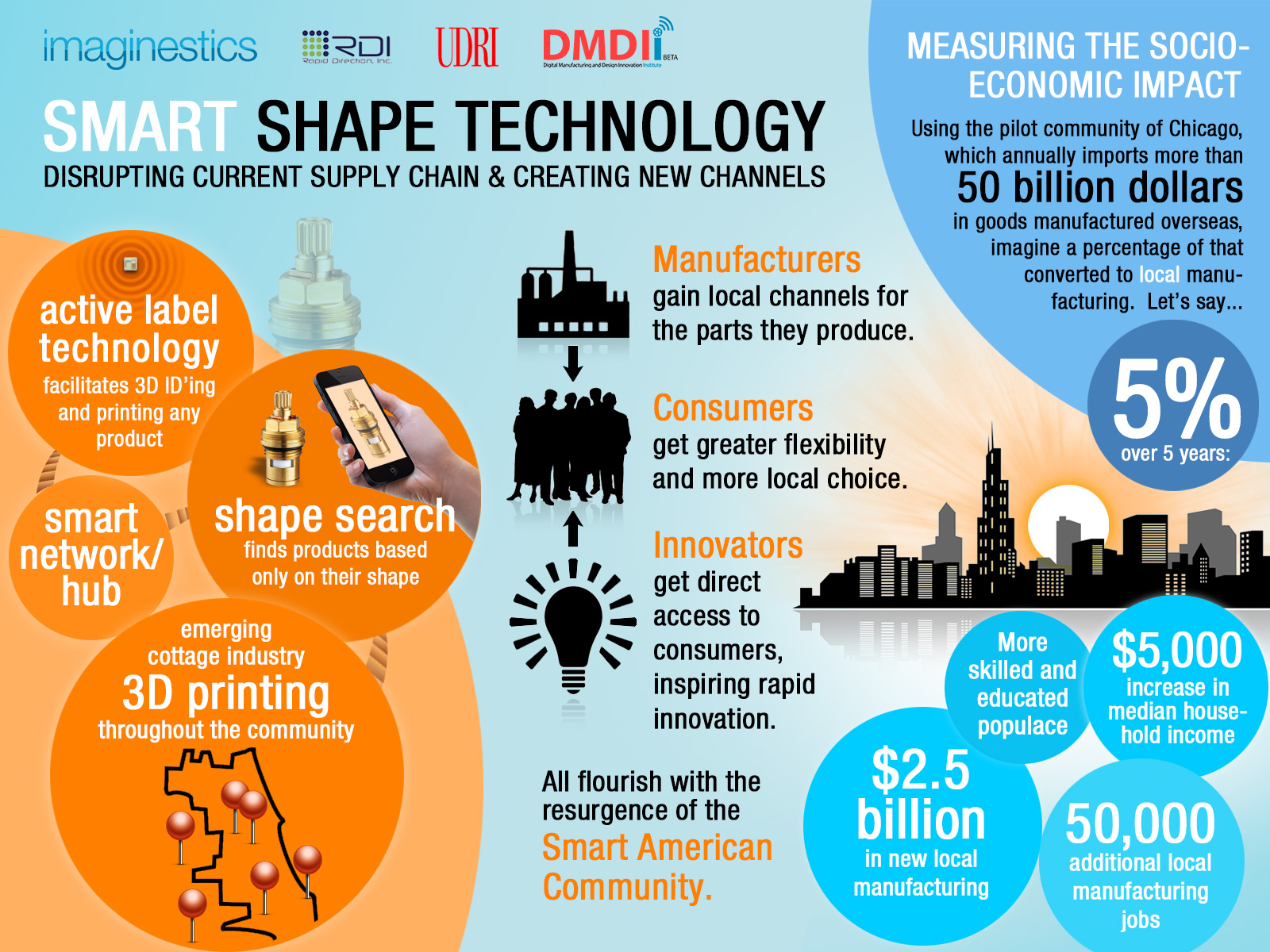

Smart Shape Technology (SST) completely disrupts current supply-chain channels, where today a consumer or manufacturer may only have one channel to gain visibility and to procure parts/products. Consumers or Manufacturers often go to retail stores or shop using catalogs/web to find parts/products. SST changes this paradigm by bringing awareness of local part/product availability (within 30 – 60 mile radius) at users’ fingertips, via mobile devices and wireless chips embedded on a part (active label) that contains 3D Design data and links to smart hubs to communicate its availability, location, and shape signature information via VizSpace, a social supply chain cyber platform. This unique SST framework allows users to make smart decisions, whether it is to quickly find a part/product to fix that leaky faucet or have an option to 3D print the part using 3D data at your neighborhood 3D printer. By virtue of providing these options, SST gives consumers’ access to retailers and local manufacturers and vice versa. This simple shift in choice has significant socio-economic impact for the American community. Let’s use Chicago as a pilot community, which imports over $50B of finished goods. SST creates resurgence in local manufacturing by merely shifting 5% of imports to be produced locally, which is $2.5B in local economic impact and 50,000 new manufacturing jobs. Furthermore, each manufacturing job creates 2.3 additional jobs in service sector. Through this local manufacturing demand, SST helps increase STEM graduates and raises local skill level and median household income by 10%.

Smart Shape Technology (SST) completely disrupts current supply-chain channels, where today a consumer or manufacturer may only have one channel to gain visibility and to procure parts/products. Consumers or Manufacturers often go to retail stores or shop using catalogs/web to find parts/products. SST changes this paradigm by bringing awareness of local part/product availability (within 30 – 60 mile radius) at users’ fingertips, via mobile devices and wireless chips embedded on a part (active label) that contains 3D Design data and links to smart hubs to communicate its availability, location, and shape signature information via VizSpace, a social supply chain cyber platform. This unique SST framework allows users to make smart decisions, whether it is to quickly find a part/product to fix that leaky faucet or have an option to 3D print the part using 3D data at your neighborhood 3D printer. By virtue of providing these options, SST gives consumers’ access to retailers and local manufacturers and vice versa. This simple shift in choice has significant socio-economic impact for the American community. Let’s use Chicago as a pilot community, which imports over $50B of finished goods. SST creates resurgence in local manufacturing by merely shifting 5% of imports to be produced locally, which is $2.5B in local economic impact and 50,000 new manufacturing jobs. Furthermore, each manufacturing job creates 2.3 additional jobs in service sector. Through this local manufacturing demand, SST helps increase STEM graduates and raises local skill level and median household income by 10%.

Team Members

- Imaginestics, LLC – Nainesh Rathod

- Digital Manufacturing and Design Innovation Institute – Dean Bartles

- Rapid Direction, Inc. – Brent Cox

- University of Dayton Research Institute (UDRI) – Larrell Walters